RK-1360 360 Degree Optical Sorting Machine Auto Image Screening Equipment for Screw Fastener Nut Parts

Brand : RKE

Product origin : CHINA

Delivery time : 30days

Supply capacity : 600/year

1. Equipped with AI software, 360 degree image analyst of different angles of surface defects, such as damaged thread and head crush. 2. Can be added 5-10 Cameras based on your cases. 3. Design for products need high accurate inspection.

Auto Screws RK-1360 360 Degree Optical Sorting Machine Manufacturers

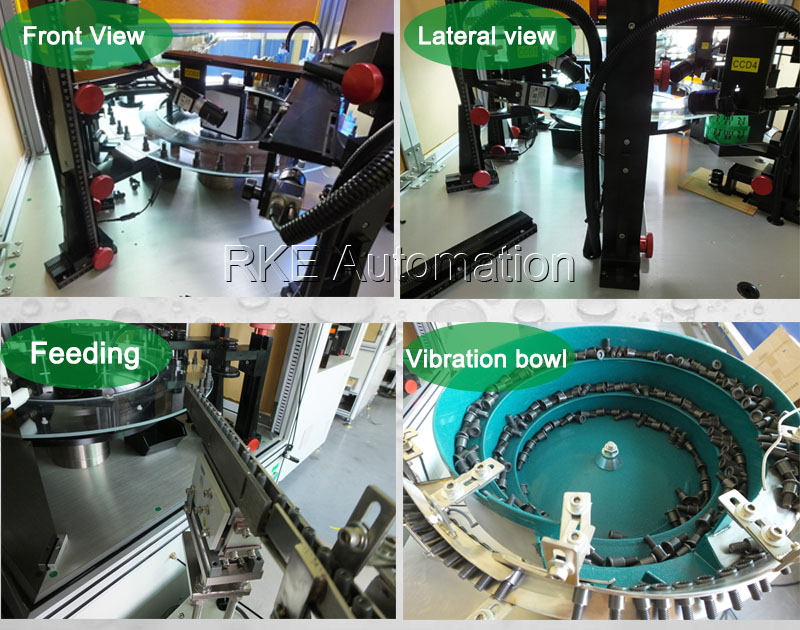

1. Product introduction

Optical Sorting Machine utilizes industrial image processing through the use of cameras mounted over production lines for inspection without operator intervention.

When it comes to inspection, there are many different variables that come into play to get accurate and precise measurements. Each of our product lines of inspection equipment has been designed around different handling and feeding concepts to allow us to provide a solution for inspection and quality for virtually any style of parts or products.

We build high speed inspection systems to inspect a variety of parts including screws. Whether you need a simple sorting machine for construction screw or a high end machine for aerospace applications, we can help!

2. Capable of Detection:

Automobile parts | Auto Fastener nut |

Precision screw | insert nuts |

Micro part | Faster part |

Stamping part | Fuel pipe union |

Semiconductor element | Other special hardware parts,etc |

3. Inspection parameters:

Including Dimensional characteristics, Head damage, Bit verification, Thread verification, Thread damage, Heat treat verification, Plating verification, Crack defects...

And more!

Diameter, Hole diameter | Roundness |

Length | With mark |

Width | With coating |

Height, Thickness | With cut/tapering |

Surface defect | Parallel edge length |

Different shape | Broken pin, Recess depth |

Crack | With thread |

Deformed, Broken | Fine or coarse thread |

Burrs, Chips | Thread numbers |

Across Corner | Pitch |

Across Flat | Slanted thread |

Chamfer angle | Minor diameter |

Included angle | Major diameter |

Arc radius | Hardness |

Concentricity | Recognition of different materials |

Heat treatment |

4. Products Parameter for 360 Degree Optical Sorting Machine Manufacturers:

| Model: | RK-1360 |

Head Diameter: | Ø5.0-Ø15mm |

Head Thickness: | Ø2.0-Ø10mm |

Height(mm): | 5mm-50mm (Can be placed on the glass plate evenly.) |

Sorting Accuracy: | ±0.02mm (Based on the reference products supplied by customers as screening criteria for identification.) |

Sorting Speed: | 300-1200pcs/min, According to individual case (objects and feeding system). |

Air Pressure(kg/cm): | 5kg/cm |

| Mainframe computer | Industrial pc |

| Digital camera | German CCD |

| Net weight(KGS) | 700 |

| Size | 1400×900×1800(LWH) |

Description for CCD Screening: | 1)CCD1 Level Vision 2)CCD2 Upside 45°Vision 3)CCD3 Downside 45°Vision 4)CCD4 Lateral Vision 5)CCD5 Upward Detection 6)CCD6 Downward Vision |

5.360 Degree Optical Sorting Machine Manufacturers Features:

1.The installation of 360° camera which can meet customer's higher detection requirements and can be more comprehensive to detect the size of the screw accurately.

2. Designed For general fastener size, and can detect the products screw nuts, aviation fasteners, auto parts, mobile phone accessories, rubber pieces, electronic products, hardware products.

3. Can be added 5-7 Cameras based on your cases.

4. Can increase the automatic packing machine and automatic feeding machine according to customer’s demand.

5. Replacement parts fast, simple operation.

6. User-friendly software.

6. CCD Camera Advantages of Optical Sorting Machine Manufacturer:

The vision machine system is based on high-precision Gemany Industrial CCD Camera, and is used for precise dimensional measurements.

7. Details for 360 Degree Optical Sorting Machine Manufacturers:

8. Flow Chart:

9. Packaging Details:

Auto Fatener nut optical sorting machine

Our products use professional wooden cases.

Package size will depend on each model size.Or according to the orders.

Delivery Time:

Delivery by shipping, about 30 working days after confirm deposit.

10. Company Introduction:

11. Certification and Patent:

Multiple

Copyright of computer software

RKE Automation

Senior Engineer-Independent research and development

12. After-service:

1, One year free warranty;

2, Enjoy lifelong maintenance;

3, Professional service team, to provide 365 days and 24 hours of technical support;

4, On-line remote service.