Overview of Automatic Vision Inspection Technology

Overview of Automatic Vision Inspection Technology

Brief introduction of automatic vision inspection technology

As the name implies, automatic vision inspection technology endows the machine the visual function as human to realize various functions, such as inspection, judgement, identification, measurement and positioning, etc., and to significantly improve production efficiency, automation and intelligent in various industries. A typical automatic vision inspection system mainly consists of light source, lens, camera, image processing hardware, image processing software, execution unit and so on.

Automatic vision inspection technology integrates the technologies of optics, mechanism, electronics, computer hardware and software, and involves various fields, such as image processing, model identification, artificial intelligent and the opto-mechatronic technology. In recent years, the rapid development of image processing and artificial intelligence has greatly promoted the development of automatic vision inspection technology.

Operation theory of automatic vision inspection technology

Automatic vision inspection technology can convert light signal into image signal and deliver to image processing software through image acquisition hardware (camera, lens, light source, etc.)

Based on the relative information of pixel brightness, color distribution, etc., image processing software can acquit characteristics from the object and make corresponding judgement, so as to control the on-site machine for realizing the inspection function according to the output data.

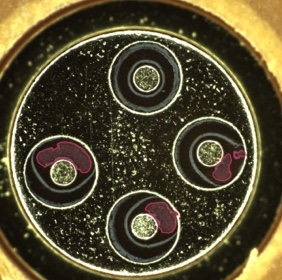

Vision processing system includes two aspects: hardware and software. On the basic of the difference of the hardware, it can be classified into smart camera and PC based vision system. The core part of a PC based vision system includes light source, lens, camera and vision processing system.

The main function of the lens is to image the measured target onto the photosensitive chip of the camera.

The main function of the camera is to convert the light signal into electrical signal and output the image to the computer.

The core technology of the software is image processing and analysis algorithm, including image enhancement, image segmentation, feature extraction, image recognition and analysis. Through image processing and analysis, the result signal of the product quality judgment and size measurement is transmitted to the corresponding hardware for display or execution.

Comparison between the automatic vision inspection technology and artificial vision inspection technology

During the process of mass industrial production in the past, products were mainly measured, identified and analyzed by artificial vision inspection technology. Due to the low efficiency, poor stability and low accuracy of artificial vision processing, automatic vision inspection technology can greatly improve the processing efficiency and automation; however, in some dangerous working environments that are not suitable for manual operation or where human eyes are difficult to identify, such as nuclear power plant monitoring and wafer defect detection, automatic vision inspection is also commonly used to replace human eyes; moreover, automatic vision inspection is easy to realize information integration, which is one of the basic technologies to realize computer integrated manufacturing.

Because quick efficiency to obtain a large amount of information, process and integrate information automatically in the process of modern automatic production, the automatic vision inspection technology is widely used in assembly positioning, product quality inspection, product identification, size measurement and so on.