Machine Vision Technology Application in the Field of High-precision Machining

Machine vision has a wide range of industrial applications, and its core functions include measurement, detection, recognition, positioning and so on. The industrial chain can be divided into upstream component market, midstream system integration / complete equipment market and downstream application market. In the upstream of machine vision, there are software and hardware providers such as light source, lens, industrial camera, image acquisition card and image processing software. In the midstream, there are integration and whole machine equipment providers. The downstream applications of the industry are wide. The main downstream markets include electronic manufacturing industry, automobile, printing and packaging, tobacco, agriculture, medicine, textile and transportation.

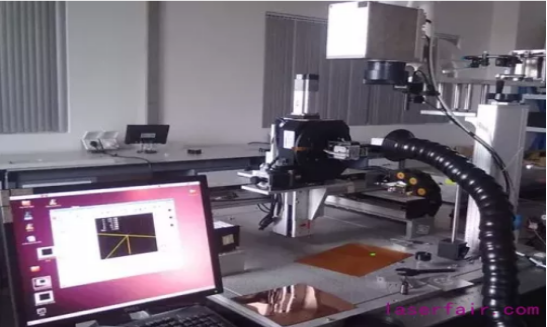

The laser processing industry introduces machine vision and uses industrial cameras instead of human eyes to detect the processed objects. The resolution and frame rate can be selected according to the processing requirements to improve the defects of artificial vision; The use of machine vision technology can also accurately locate the machined parts, which can not only save the expensive and heavy fixture cost, improve the machining accuracy and ensure the quality, but also carry out continuous accurate operation and speed up the work efficiency.

At present, machine vision technology is most widely used in high-precision machining fields such as laser cutting, laser welding, laser marking and laser micromachining. Let's learn about the application of machine vision technology in laser processing industry:

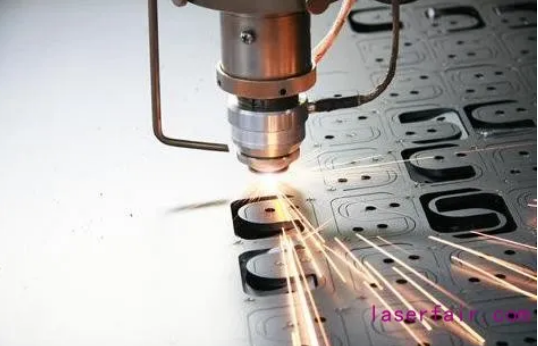

01 laser cutting

Machine vision is used for laser cutting. Guiding laser cutting can make the product cutting line accurate, the edge smooth, and easily cut out any desired shape and size. Laser cutting is used in the automotive industry, semiconductor industry, mold industry, raw material industry, consumer goods manufacturing industry and aerospace industry. Specific applications include wafer cutting, FPC flexible circuit board cutting, label / leather cutting, auto parts cutting, etc.

02 laser welding

Laser welding occupies an important position in precision instrument welding because of its advantages of no welding pollution and invisible change, and machine vision guidance is the icing on the cake. Specific applications such as automobile body steel plate welding, battery welding, cardiac pacemaker, sealed relay, etc.

03 laser marking

Laser marking is widely used in all kinds of materials and almost all industries. Machine vision guided positioning aims at fragile materials, small target size, high positioning accuracy and continuous mass marking operation, which can effectively improve production efficiency and ensure product quality consistency. Specific applications include IC marking, consumer electronics marking, auto parts marking, vamp marking, etc.

04 laser micromachining

Laser micromachining includes fine machining methods such as engraving and resistance adjustment, which will produce large errors in human eye judgment. Machine vision can clearly locate the processing area and guide the laser to work with as little error as possible. Specific applications such as laser resistance modulation, thin film solar cell scribing, etc.

The introduction of machine vision technology into the laser processing industry effectively improves the accuracy, intelligence and automation performance of laser processing equipment, meets the quality requirements of mass and large-scale production in modern industry, reduces the generation of defective products, saves costs and promotes the rapid development of enterprises.

Statement: part of the content comes from the Internet and is only for the purpose of readers' learning and communication. The copyright of this article belongs to the original author. If there is anything wrong, please contact to delete.