Inspection Application in Semiconductor Industry

With the properties of portable volume, dense array and high demand of accuracy, semiconductor is an organic material,

which conductive property is between the conductor and the insulator. Semiconductor industry has covered various fields,

from the processor and memory of PC or mobile device, from integrated circuit to solar battery, especially playing vital role in 3C electronics industry and communication industry. The popularity of automated inspection machine can really solve the quality inspection problem of the semiconductor. The following will introduce our several applied cases in semiconductor:

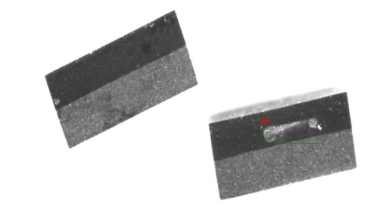

1. Button battery small defect inspection:

High accurate inspection system can correctly identify the small defect of the button battery.

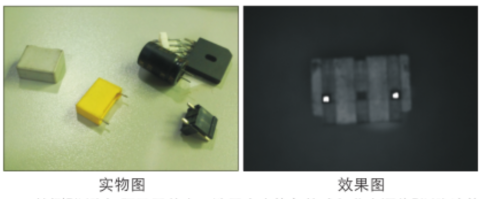

2. PIN positioning of electronic components:

PIN space and evenness detection.

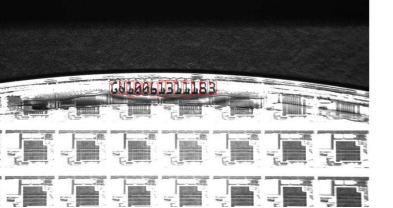

3. Wafer positioning and OCR recognition:

Wafer accurate positioning is an important link in semiconductor quality inspection.

Wafer OCR recognition, second speed reading inkjet characters.

4. Capacitance defect detection:

Simultaneously detect and classify several checkpoints on the capacitance.

5. LED surface defect detection:

Detect surface damage, scratches, dirty on the LED light.

With stricter demand on semiconductor industry, RKE Intelligent will continuously keeping technology creation in semiconductor automation inspection.