How to Judge the Merits of Automated Optical Sorting Machine

How to judge the Merits of Automated Optical Sorting Machine

In recent years, with the requirements of accuracy and delivery time have become more and more strict, automatic screening machines are gradually favored by fastener manufacturers, and will inevitably become an indispensable role in the highly competitive fastener industry in the future.

With the large number of fasteners used in all works of life, optical sorting machines have mushroomed. For fasteners manufacturers, it is imperative to carefully select a Automatic sorting machine that can detect a variety of products and can apply to different sizes of detected products, to meet the value of the industry’s investment in sorting machine industry. Therefore, how to judge the merits of automation optical sorting machine becomes a top priority.

1. Sorting Speed:

Speed determines the production capacity. The speed must be taken into account if one uses the automatic optical sorting machine to replace a large number of labor detection, .

2. Sorting Accuracy:

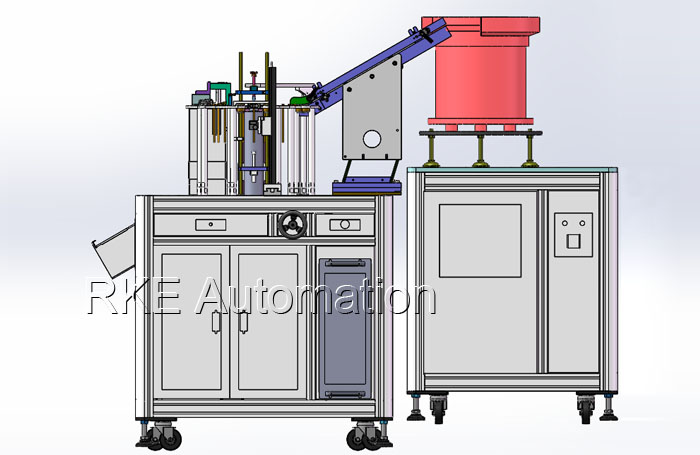

Most of us think that one must improve the CCD Camera configuration first if they wanna increase the Sorting accuracy. In fact, accuracy will be affected both by Light and CCD. Most of the vision machine manufacturers will recommend you purchase high precision CCD Camera, Screw Optical Sorting Machine, to improve the detect accuracy, but in many cases, the appropriate light source and lens can meet the requirements of customers, don’t forget that high-precision CCD cameras also will increase the computer processing time and affect the detect speed.

3. Share-ability:

Fasteners, with thousands of processed parts styles, also have different size models. The customers must consider the style of the parts and the share-ability of the sorting machine while choosing an automatic Screening Machine. Some of the Optical Sorter Machine can only be applied to one product, even to a single size. As a result, it is impossible to bring the investment of the industry to a better benefit. and it can fails to achieve the main purpose of replacing manpower detection and saving cost. It is a big burden on cost expenditure for fasteners manufacturer with diverse products.

4. Integrity:

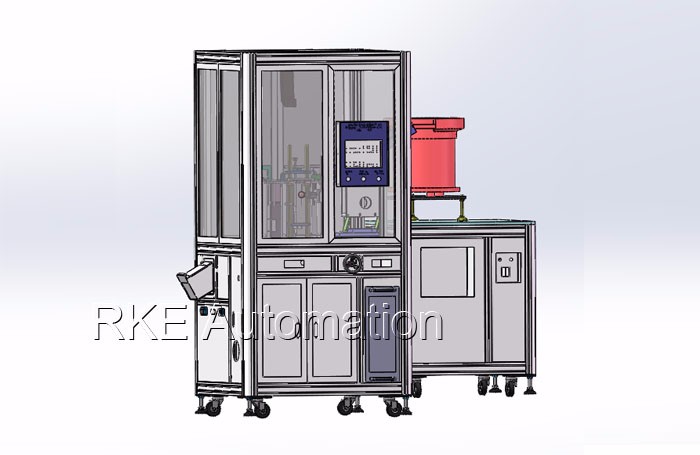

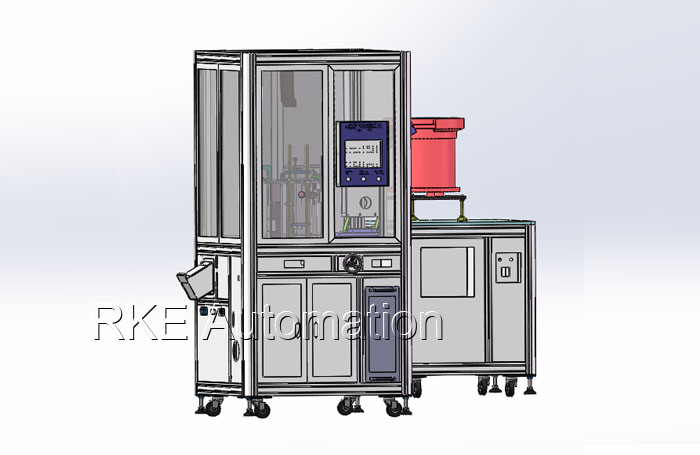

The optical requirements and the machine mechanism design should be taken into consideration while purchasing screening machine. Whether the material feeding smoothly or not, the delivery of detected products and the correctness of defective products exclusion is also a great factor for the purchase of equipment.