Classification & Application of Machine Optical Inspection Technology

Inspection is an inevitable link during the whole manufacturing process in which machine optical Inspection has become a major driving force.

一、Machine Optical Inspection Technology

Application sites and scopes of machine optical inspection technology are really sweeping. Here are several = detailed classification we can do according to the different inspection projects:

(一)Accoding to the inspection contents: positioning, defect inspection, counting or loss inspection, and demension measurement, etc.

(二)According to the devised system: online inspection system, and offline inspection system.

(三)According to the technology: stereo vision inspection, spot inspection, demdension inspection, OCR, etc.

The vital function of machine optical inspection technology is to eliminate the defects of products measured so as to ensure the entity of their function and quality. In modern manufacturing, machine optical inspection technology almost pernetrate into various industries to detect assorted products.

Vision system has strong function presented by that any defect, shape, and color of 3C electronics can be recognized.

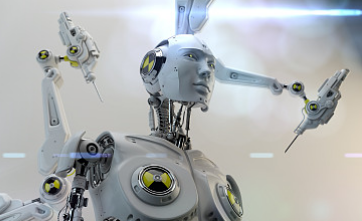

It's remarkable that machine optical inspection technology almost covers all walks of life, such as products’packaging inspection, paper quality inspection, metal parts quality inspection and AI intelligent manufacturing where robot can be seen various assembly lines.

In significance, machine optical inspection technology has winned higher profits and wider space for modern enterprises. It can content the inspection needs of assorted products and eliminate some defective products so as to promote the productivity and economic benefits for the customers.

Machine vision technology has been an indispensible impetus for national industrial manufactiuring and a strong branch of modern emerging technology so as to be a new drive force and solid technology support for the enterprises’research and development.